About Us

Our Story: From a Single Spark to an Integrated Fire

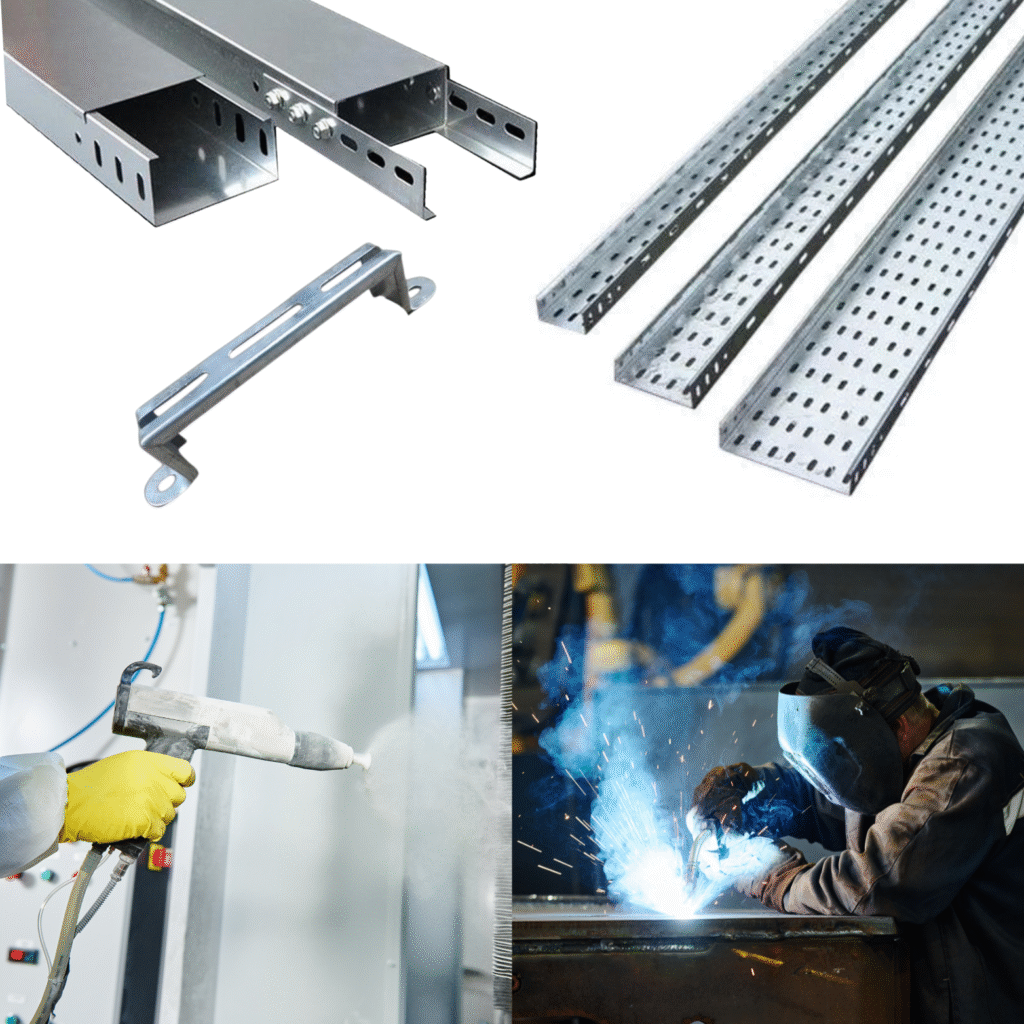

Our journey began with a vision to redefine quality in metal fabrication. What started as Varalakshmi Sri Pre Fab, a specialized unit focused on cable trays and custom fabrications, quickly earned a reputation for durability and precision.

As our clients’ needs grew more complex, so did we. Recognizing the demand for robust metal processing, we established Sri Raja Rajeswari Engineering Works in 2024, adding heavy-duty shearing and bending to our arsenal. This allowed us to control the very first step in the manufacturing chain, ensuring quality from the ground up.

But our vision didn’t stop there. A product is only complete when it is protected. In 2025, Shreya Powder Coating was born, completing our vertical integration by providing superior, durable finishing that stands the test of time.

Today, the Sri Lakshmi Engineering Group stands as a testament to strategic growth and client-focused evolution—a single source for all metal engineering needs.

Quality in Every Weld

Reliability You Can Build On

Our Core Values

Innovation Through Integration

Partnership Beyond the Transaction

Our Mission

Our Vision

Our Machinery & Facilities: Engineered for Precision

Our commitment to quality is backed by a robust and versatile fleet of machinery, enabling us to handle a wide range of materials and specifications with unmatched precision.

Power Presses for Stamping and Forming:

40 Ton Power Press – 1 No.

30 Ton Power Press – 1 No.

20 Ton Power Press – 3 No.

10 Ton Power Press – 3 No.

Press Brake Bending for Accurate Angles:

6mm Press Brake Bending with 2500mm (2.5m) Length Capacity

2mm Press Brake Bending with 2500mm (2.5m) Length Capacity

Specialized Fabrication Machinery:

1200mm Perforation Machine with 3mm Thickness Punching Capacity

Shearing Machine for 4mm Thickness and 2500mm (2.5m) Length

Varalakshmi Sri Pre Fab

The Art of Fabrication

ESTABLISHED: 2017

FOCUS: Custom metal fabrication and cable management systems.

LEGACY: Our founding division, this is where our passion for precision took shape. We specialize in manufacturing high-quality cable trays (Perforated, Ladder, Raceway) and custom fabrications that form the backbone of industries across Hyderabad and beyond.

Sri Raja Rajeswari Engineering Works

The Power of Precision Processing

ESTABLISHED: 2024

FOCUS: Heavy-duty metal shearing and bending services.

MISSION: To handle the large-scale, tough jobs. With the capacity to shear 16mm thick plates and bend 6.3-meter lengths, we bring raw power and exacting accuracy to the first stage of production.

Shreya Powder Coating

The Armor of Perfection

ESTABLISHED: 2025

FOCUS: High-quality, durable powder coating finishes.

VISION: To ensure that every product we deliver is not only functionally superior but also aesthetically flawless and protected against corrosion for years to come.

Our Team

Mr. CH. Sathi Babu

Director-Sri Rajarajeshwari Engineering Works

Mr. CH. Sathi Babu

Director-Sri Rajarajeshwari Engineering Works

- Phone:+91 9573695613

- Email:ganeshshiva088@gmail.com

Mr. M. Shiva Ganesh

Director-Varalakshmi Sri Pre Fab

Mr. M. Shiva Ganesh

Director-Varalakshmi Sri Pre Fab

- Phone:+91 8686958258

- Email:ganeshshiva088@gmail.com

Mr. Naveen Kumar.B

Director-Shreya Powder Coating

Mr. Naveen Kumar.B

Director-Shreya Powder Coating

- Phone:+91 8074180975

- Email:ganeshshiva088@gmail.com

Testimonials

Frequently Asked Questions

We are a vertically integrated group. This means we control the entire manufacturing process under one roof—from heavy shearing and bending to custom fabrication and powder coating. This unique structure allows us to ensure consistent quality, offer competitive pricing, and deliver faster turnaround times than our competitors.

We serve a wide range of industries including Construction & Infrastructure, Power & Energy, IT & Data Centers, Industrial Manufacturing, Telecommunications, and Automotive. Our versatile capabilities allow us to adapt to the specific needs of any sector that requires metal fabrication.

Through our Sri Raja Rajeswari Engineering Works division, we can shear plates up to 6,700 mm in length and 16 mm in thickness and bend plates up to 6,300 mm in length.

We specialize in both! While we have a range of standard products like cable trays and brackets, a significant part of our business is Custom Fabrication. We can build components from your technical drawings or help design a solution from scratch.

Powder coating is a dry finishing process where a powder is electrostatically applied and then cured under heat to form a hard, durable layer. It is better than traditional paint because it is more resistant to chipping, scratching, and fading; it provides a more uniform finish; and it is an more environmentally friendly process.

Option 1: Online Quote Request Form (Recommended)

The fastest way is to use our Online Quote Request Form on our [Contact Us] page. Simply fill in your details and project requirements, and our team will get back to you with a detailed quotation.

Option 2: Email Us

You can send us a detailed email at ganeshshiva088@gmail.com. Please include the following information for a faster and more accurate quote:

Your name, company name, and contact details.

Project description and intended use.

Technical drawings, sketches, or CAD files (if available).

Material type (e.g., mild steel, stainless steel) and thickness.

Dimensions, quantities, and any special tolerances.

Preferred finish (e.g., powder coating color, self-color).

Option 3: Call Us Directly

For immediate discussion or complex projects, call us at +91-8686958258 or +91-8143568818. Our technical team can guide you on the information needed and provide preliminary advice.